Outside Plant (OSP)

ICCES have more than seven years of experience in the design and implementation of Fiber Optic Infrastructure.

ICCES specializes in the process of physically installing and completing fibre optic networks, turning network designs into operating systems. Our teams of experienced technicians work closely with our clients in every stage of installation project; design, project management, installation, testing, troubleshooting, documentation and restoration.

OSP installations include installing aerial cable, direct-buried cable, underground cable in conduit or installing conduit or inner-duct and then pulling cable. Our teams are equipped and trained to install all network configurations including complex links that may include several types of installation, for example aerial in one section, pulling in conduit on a bridge crossing and burying the rest of the cable.

As the need for broadband networks increases, fiber deployments will continue to accelerate globally. Outside plant fiber optic backbone and fiber-to-the-home (FTTH) deployments can be very challenging.

ICCES Outside Plant service solution addresses these challenges by designing and building the physical infrastructure for your outside plant fiber optic backbone routes and FTTH access networks

With Whom We Work

- Underground cables are pulled in conduit that is buried underground.

- If the geography allows, some fiber optic cables can be buried directly in the ground by plowing or trenching directly into the ground and placing the cable in the trench.

- In aerial configurations the fibre optic cables can be lashed to support messenger cable

Our Expertise

- Survey, planning design and implementation.

- Submittals and approvals (design, materials, & work procedure).

- Making of fusion and mechanical Splicing for all types of Fiber Optic Cables according to the client’s requirements of the splicing attenuation of the Cables.

- Installation of Fiber Cables, Optical Fiber distribution frames inside the complexes and making the termination ends of the Cables for all types of connectors using types of techniques (crimping, epoxy and polishing) for SM, MM and RIBBON Cables.

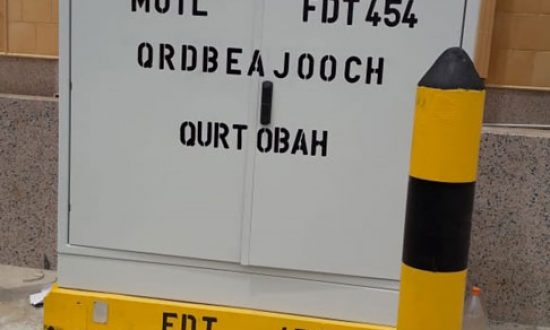

- Installation Fiber Optic Cables in manholes, direct buried and overhead cables.

Very recently, ICCES delivered WIFI networks running over fiber optic infrastructure in all Royal Protocol palaces in the Eastern Province in addition to all other fiber optic jobs executed in other parts of the kingdom, both Royal, government and private.

ICCES have been successfully carried out a number of OSP project. Some of our valuable Clients are:

- AL MANAR ARABIAN CORPORATION, DAMMAM (STC)

- PAN GULF TELECOM COMPANY, AL KHOBAR(STC)

- TELECOMMUNICATION CONSULTANTS INDIA LTD (STC, MOBILY, DAWIYAT)

- FIBNET (STC)

- ROYAL PROTOCOL

- INTERCONTINENTAL HOTELS GROUP (IHG)